Takt time production schedules material deliveries on site

At YIT's Asemanmäki parking facility, ready-mix concrete orders from Rudus were carried out digitally using Carinafour and Platform of Trust solutions.

Takt time production is becoming more common on construction sites. It raises the requirements for material deliveries to a new level, when the construction site must have the right amount of materials, in the right place and at the desired time.

The process-oriented, takt time production-based, way of working in industrial construction raises the requirements for material deliveries to a new level: Deliveries must be successful as desired so that production on site is not disturbed. The transformation of the working methods brought about by takt time production requires digital material flow management, in which orders to the construction site are managed in the site's logistics system, from where the processing of orders to suppliers is carried out completely digitally. This automates the manual work done today and makes it easier for the construction site and suppliers to work.

In practice, takt time production aims to make more deliveries to construction sites in smaller deliveries to a reasonable extent, and building materials are not stored on site. Delivery reliability and the management of changes and deviations are increasingly important for the success of the construction site. In addition, an accurate work package-specific parts list is formed in the site's logistics system, which can be used, for example, to automate the calculation of emissions data or for maintenance to tell what materials and products the building is made of.

The construction site of the Asemanmäki parking facility is a forerunner

"With CALS, we have been managing the supply chains of general cargo in the project industry for a long time, and the benefits achieved have been proven. In Asemamäki, it has been really great to be involved in developing the material flows of frame and concrete masses together with YIT, Betset, Rudus and PoT. Yes, it is true that the idea of joint material information management of the entire network also generates significant value in castings and element frames," continues Ari Viitanen, owner of Carinafour.

The Asemamäki car park, to be built in 2022, is one of YIT's industrial construction sites with an advanced digital takt time production system. Digital order processing was a good experience for the concrete supplier, Rudus.

"Our experience with digital order processing at the Asemamäki site was very positive. In practice, site orders were directed directly to our order processing system, and the biggest concrete benefit was the reduction in manual work in order processing. This also reduced human error, and digitalization also brings transparency to process development. We have been developing digital solutions for our customers for years, and cooperation with YIT was a great opportunity, a natural continuation and a value-added thing for our development work," says Mika Moisander, Development Director at Rudus.

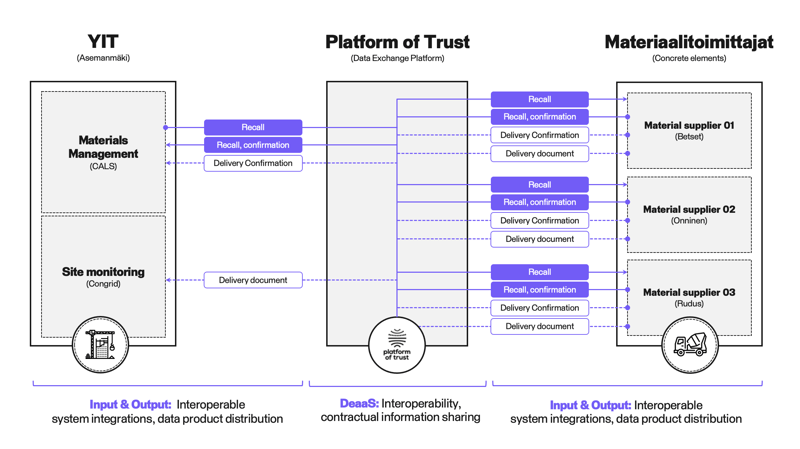

The Platform of Trust used in the Asemamäki parking facility is an information exchange platform on which different operators can develop their services. It operates according to the principles of the modern platform economy in a two-way manner, allowing each actor to both utilize and enrich the data there.

"The Platform of Trust acts as an interpreter between the systems of actors who speak different languages, ensuring that the entity works seamlessly and can be controlled according to the needs of the end users. The digitalization of order processing in conjunction with Carinafour's CALS system is one of our first use cases in industrial construction. Of course, we are actively developing the functionality of our platform, and in connection with this, it was interesting to test the automation of the delivery of material documents at the Asemanmäki site," says Pekka Aalto, Commercial Director of Platform of Trust, which promotes the digitalisation of the construction industry.

Industrial construction in a nutshell

Industrial construction refers to a process-oriented (takt time production), standardised way of construction, in which part of the work traditionally done on construction sites is transferred to factories and in which the operating model is constantly improved based on the information gathered from different parties involved in construction. The digital materials management system on the construction site is an important part of industrial construction.

YIT's goal is to expand digital material flow management in takt time production projects, and to further develop the solution together with material and technology suppliers so that its benefits can be made available to all parties.

The article was originally published here.